The Seabird Island Sustainable Community Demonstration Project is the first of its kind in the world. While other research and prototype developments have advanced the concepts and principles of sustainable housing, the Seabird Project has assembled a whole range of strategies, new technologies, innovations, and new products to demonstrate an integrated approach — sustainable environmental design.

A member of the Sto:lo First Nation, the Seabird Island community,located in British Columbia five miles north of Agassiz on the Fraser River, contains 1,943 floodplain hectares, of which 730 hectares are cultivated. The remaining 1,213 hectares are used for residences, community buildings, forestry, rights-of-way, and economic development projects. Project planning and design for its new, sustainable housing development began in May, 2002, and is now at over 65% completion. The Canada Mortgage and Housing Corporation (CMHC) Assisted Housing Department has partnered with Indian and Northern Affairs Canada (INAC) and the Seabird Island First Nation, along with many sponsoring suppliers and manufacturers, to demonstrate a new way of financing and building affordable housing projects. The Seabird Island units have largely been financed by the regular ‘NHA Section 95’ program for social housing on-reserve, and will be rented to band members who have been on a new housing waiting list for a number of years. One of the housing units will remain open for tours and public education over the next two years.

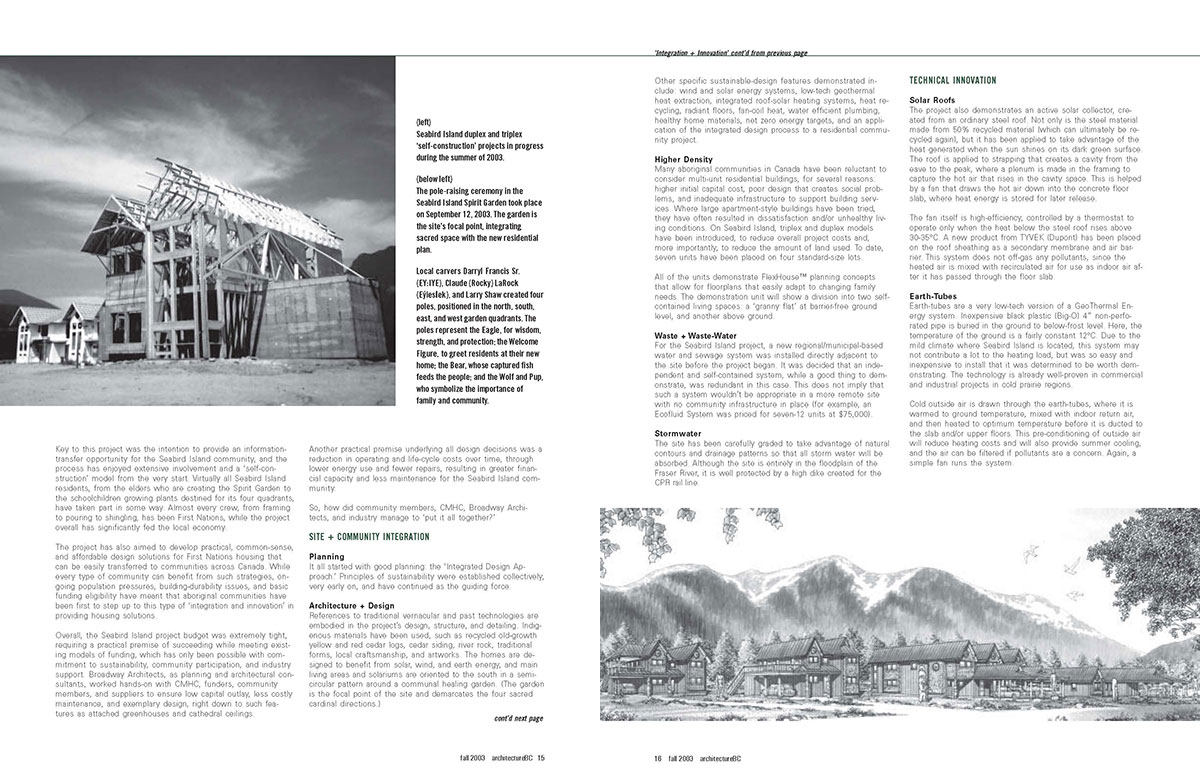

Key to this project was the intention to provide an informationtransfer opportunity for the Seabird Island community, and the process has enjoyed extensive involvement and a ‘self-construction model from the very start. Virtually all Seabird Island residents, from the elders who are creating the Spirit Garden, the school children growing plants destined for its four quadrants, have taken part in some way. Almost every crew, from framing to pouring to shingling, has been First Nations, while the project overall has significantly fed the local economy.

The project has also aimed to develop practical, common-sense, and affordable design solutions for First Nations housing that can be easily transferred to communities across Canada. While

every type of community can benefit from such strategies, ongoing population pressures, building-durability issues, and basic funding eligibility have meant that aboriginal communities have been first to step up to this type of ‘integration and innovation’ in providing housing solutions

Overall, the Seabird Island project budget was extremely tight, requiring a practical premise of succeeding while meeting existing models of funding, which has only been possible with commitment to sustainability, community participation, and industry support. Broadway Architects, as planning and architectural consultants, worked hands-on with CMHC, funders, community members, and suppliers to ensure low capital outlay, less costly maintenance, and exemplary design, right down to such features as attached greenhouses and cathedral ceilings.

Another practical premise underlying all design decisions was a reduction in operating and life-cycle costs over time, through lower energy use and fewer repairs, resulting in greater financial capacity and less maintenance for the Seabird Island community. So, how did community members, CMHC, Broadway Architects, and industry manage to ‘put it all together?’

SITE + COMMUNITY INTEGRATION

Planning

It all started with good planning: the ‘Integrated Design Approach.’ Principles of sustainability were established collectively, very early on, and have continued as the guiding force. Architecture + Design References to traditional vernacular and past technologies are embodied in the project’s design, structure, and detailing. Indigenous materials have been used, such as recycled old-growth yellow and red cedar logs, cedar siding, river rock, traditional forms, local craftsmanship, and artworks. The homes are designed to benefit from solar, wind, and earth energy, and main living areas and solariums are oriented to the south in a semicircular pattern around a communal healing garden. (The garden is the focal point of the site and demarcates the four sacred cardinal directions.)

healthy home materials, net zero energy targets, and an application of the integrated design process to a residential community project.

Higher Density

Many aboriginal communities in Canada have been reluctant to consider multi-unit residential buildings, for several reasons: higher initial capital cost, poor design that creates social problems, and inadequate infrastructure to support building services. Where large apartment-style buildings have been tried, they have often resulted in dissatisfaction and/or unhealthy living conditions. On Seabird Island, triplex and duplex models have been introduced, to reduce overall project costs and,more importantly, to reduce the amount of land used. To date, seven units have been placed on four standard-size lots. All of the units demonstrate FlexHouse™ planning concepts that allow for floorplans that easily adapt to changing family needs. The demonstration unit will show a division into two selfcontained living spaces: a ‘granny flat’ at barrier-free ground level, and another above ground.

For the Seabird Island project, a new regional/municipal-based water and sewage system was installed directly adjacent to the site before the project began. It was decided that an independent and self-contained system, while a good thing to demonstrate, was redundant in this case. This does not imply that such a system wouldn’t be appropriate in a more remote site with no community infrastructure in place (for example, an Ecofluid System was priced for seven-12 units at $75,000).

Stormwater

The site has been carefully graded to take advantage of natural contours and drainage patterns so that all storm water will be absorbed. Although the site is entirely in the floodplain of the Fraser River, it is well protected by a high dike created for theCPR rail line.

Solar Roofs

The project also demonstrates an active solar collector, created from an ordinary steel roof. Not only is the steel material made from 50% recycled material (which can ultimately be recycled again), but it has been applied to take advantage of the

heat generated when the sun shines on its dark green surface. The roof is applied to strapping that creates a cavity from the eave to the peak, where a plenum is made in the framing to capture the hot air that rises in the cavity space. This is helped by a fan that draws the hot air down into the concrete floor slab, where heat energy is stored for later release. The fan itself is high-efficiency, controlled by a thermostat to operate only when the heat below the steel roof rises above 30-35°C. A new product from TYVEK (Dupont) has been placed on the roof sheathing as a secondary membrane and air barrier. This system does not off-gas any pollutants, since the heated air is mixed with recirculated air for use as indoor air after it has passed through the floor slab.

Earth-Tubes

Earth-tubes are a very low-tech version of a GeoThermal Energy system. Inexpensive black plastic (Big-O) 4” non-perforated pipe is buried in the ground to below-frost level. Here, the temperature of the ground is a fairly constant 12°C. Due to the

mild climate where Seabird Island is located, this system may not contribute a lot to the heating load, but was so easy and inexpensive to install that it was determined to be worth demonstrating. The technology is already well-proven in commercial and industrial projects in cold prairie regions. Cold outside air is drawn through the earth-tubes, where it is warmed to ground temperature, mixed with indoor return air, and then heated to optimum temperature before it is ducted tothe slab and/or upper floors. This pre-conditioning of outside air will reduce heating costs and will also provide summer cooling, and the air can be filtered if pollutants are a concern. Again, a simple fan runs the system.

Recycled Heat Energy

The well-known fact that hot air rises has been employed at Seabird to make the most of heat energy gained from all sources: solar, geo-thermal, and fossil fuel/hydro. A duct located at the high points of the dwelling draws hotter air to the concrete slab for storage and slow release. A typical house has areas where the air is stratified and not recirculated, allowing heat energy to dissipate through the ceiling and upper walls. The whole house can be considered an integrated system that almost operates as an HRV. Current thinking among leading mechanical engineers has recently supported the “House As a System” concept as the best solution for indoor air quality.

Hydronic Radiant Floors

Known for over 2,000 years as perhaps the most efficient heating system, and widely used throughout the world today, radiant floors are finally becoming popular in North America. Seabird Island uses an inexpensive domestic hot-water system to heat water for circulation through a fan-coil unit (similar to a car radiator), where the heat is transferred to a liquid medium circulated through the concrete slab. This keeps the floor warm and comfortable and also ensures that the units do not need furnaces, providing a major capital cost saving.

Domestic Hot Water Preheat

Hot water represents, on average, about one-third of typical household energy load annually. On Seabird Island, cold water from the local source first enters a simple uninsulated steel tank located under a unit window seat. Here, hot air from the peak of the solarium is forced through on its way to the concrete floor slab, increasing the temperature of the water in the pre-heat tank from cold to room temperature. It is this pre-heated water that is then drawn to the water heater for domestic use and, in the case of Seabird, also to the fan-coil unit for space heating.

The Seabird Island project has used recycled plastic lumber for all sill plates in the framing. This material will not rot if it gets wet and eliminates any concern over long-term deterioration of key framing elements should the wall system fail to prevent water penetration.

Certified Lumber

All lumber used in this project is ISO- and SFI-certified, from Interfor’s sustainably managed forests.

Wind Energy

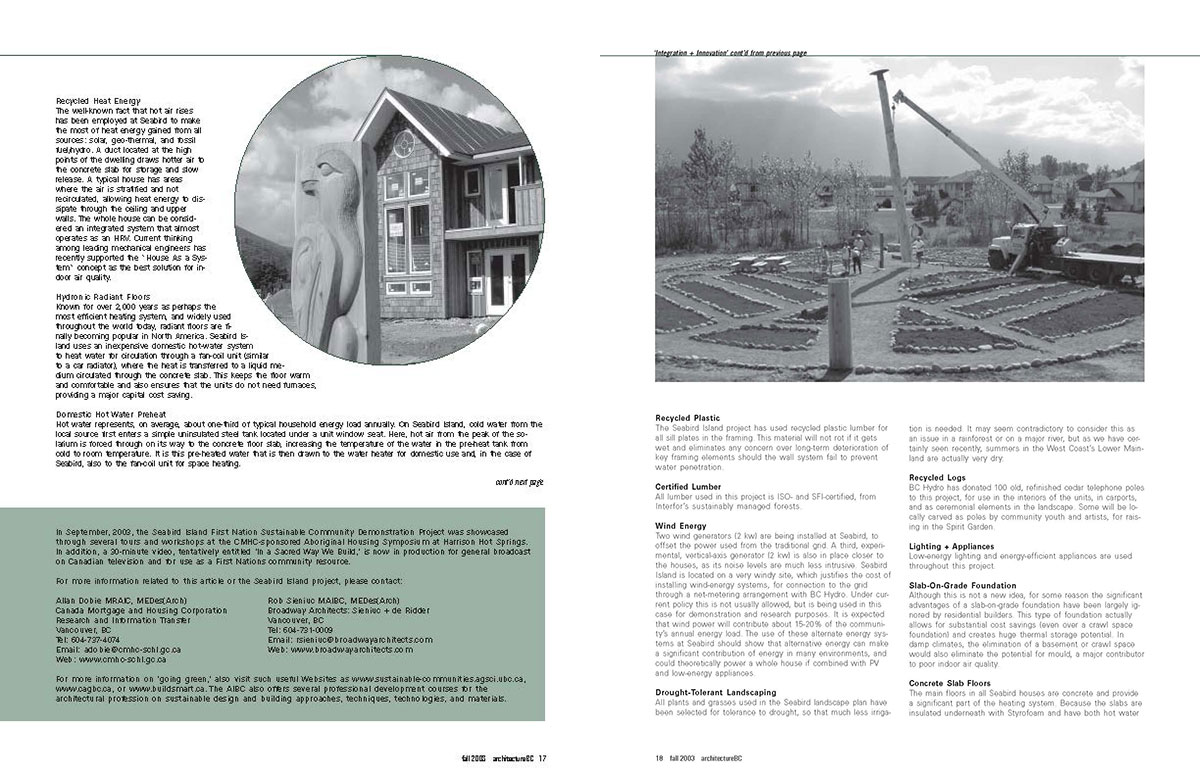

Two wind generators (2 kw) are being installed at Seabird, to offset the power used from the traditional grid. A third, experimental, vertical-axis generator (2 kw) is also in place closer to the houses, as its noise levels are much less intrusive. Seabird Island is located on a very windy site, which justifies the cost of installing wind-energy systems, for connection to the grid through a net-metering arrangement with BC Hydro. Under current policy this is not usually allowed, but is being used in this case for demonstration and research purposes. It is expected that wind power will contribute about 15-20% of the community’s annual energy load. The use of these alternate energy systems at Seabird should show that alternative energy can make a significant contribution of energy in many environments, and could theoretically power a whole whole house if combined with PV and low-energy appliances.

Drought-Tolerant Landscaping

All plants and grasses used in the Seabird landscape plan have been selected for tolerance to drought, so that much less irrigation is needed. It may seem contradictory to consider this as an issue in a rainforest or on a major river, but as we have certainly seen recently, summers in the West Coast’s Lower Mainland are actually very dry.

Recycled Logs

BC Hydro has donated 100 old, refinished cedar telephone poles to this project, for use in the interiors of the units, in carports, and as ceremonial elements in the landscape. Some will be locally carved as poles by community youth and artists, for raising in the Spirit Garden.

Lighting + Appliances

Low-energy lighting and energy-efficient appliances are used throughout this project.

Slab-On-Grade Foundation

Although this is not a new idea, for some reason the significant advantages of a slab-on-grade foundation have been largely ignored by residential builders. This type of foundation actually allows for substantial cost savings (even over a crawl space foundation) and creates huge thermal storage potential. In damp climates, the elimination of a basement or crawl space would also eliminate the potential for mould, a major contributor to poor indoor air quality. Concrete Slab Floors The main floors in all Seabird houses are concrete and provide a significant part of the heating system. Because the slabs are insulated underneath with Styrofoam and have both hot water piping and hot air tubes embedded in the concrete, the slabs provide large thermal-storage capacity and radiant heat to the space. This allows the slab to absorb daytime heat energy directly and indirectly from the sun and release this energy slowly during the night. The concrete slab also provides a contemporary-finish floor. By introducing a stain into the mix and applying careful steel trowelling, a beautiful marble-like finish is achieved that is also extremely durable. This means that once the floor is poured, it is virtually complete, which results in even greater cost savings. Maintenance and repairs are reduced, as replacement costs for carpeting and linoleum are eliminated.

High-Performance Windows

It has always been a sound policy to install the best windows that can be afforded, as these are the weak point in any wall system. At Seabird, Low-E double-glazing was used in sealed units with PVC frames and a rainscreen drainage system.

Aboriginal-Capacity Building

It has been extremely important throughout the Seabird Island project to make sure that experience and knowledge gained from the entire process can be used by the local community and transferred to other First Nations locales. The demand for more and better housing is growing rapidly right across the country, along with a rising need for qualified tradespeople to provide it. The integrated environmental design/selfconstruct model may initially seem to cost more and take longer, but as experience is gained it can result in major cost savings, since accommodation and travel costs for outside workers are eliminated. Jobs that stay in the community also result in positive spin-offs, encouraging local economic, as well as social

and environmental, sustainability.

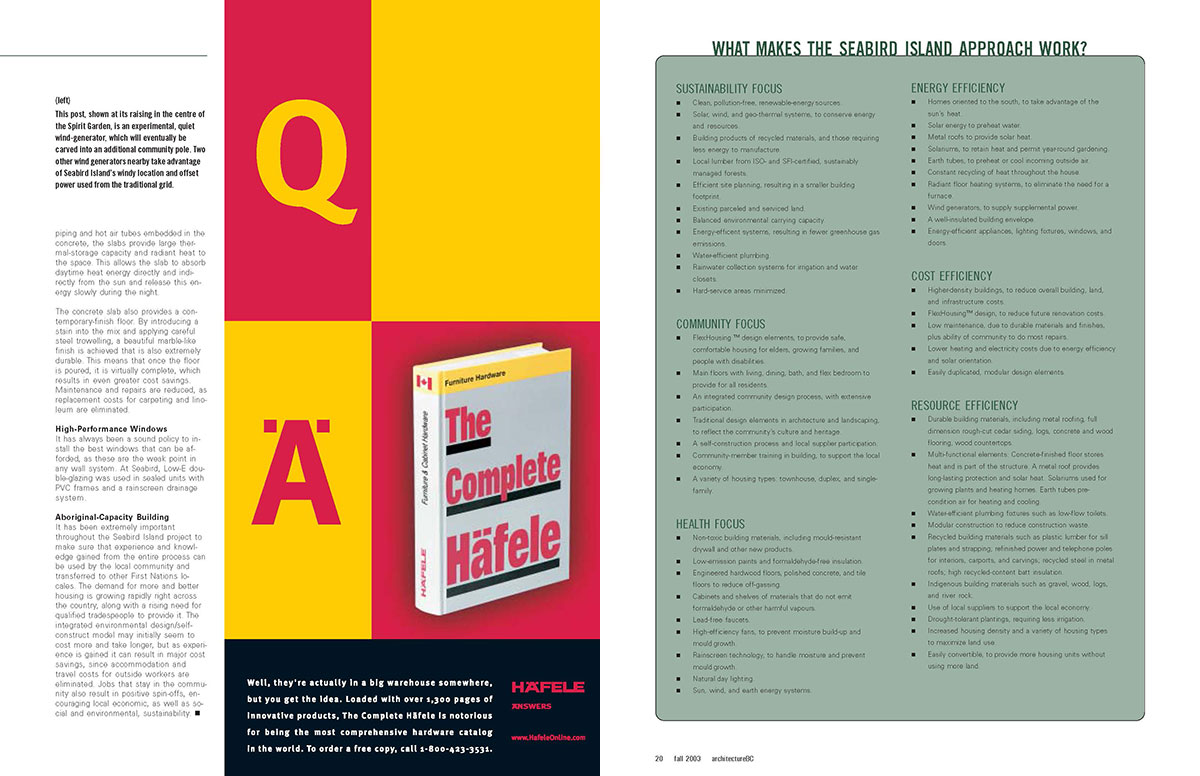

SUSTAINABILITY FOCUS

• Clean, pollution-free, renewable-energy sources.

• Solar, wind, and geo-thermal systems, to conserve energy and resources.

• Building products of recycled materials, and those requiring less energy to manufacture.

• Local lumber from ISO- and SFI-certified, sustainably managed forests.

• Efficient site planning, resulting in a smaller building footprint.

• Existing parceled and serviced land.

• Balanced environmental carrying capacity.

• Energy-efficent systems, resulting in fewer greenhouse gas emissions.

• Water-efficient plumbing.

• Rainwater collection systems for irrigation and water closets.

• Hard-service areas minimized.

COMMUNITY FOCUS

• FlexHousing ™ design elements, to provide safe, comfortable housing for elders, growing families, and people with disabilities.

• Main floors with living, dining, bath, and flex bedroom to provide for all residents.

• An integrated community design process, with extensive participation.

• Traditional design elements in architecture and landscaping, to reflect the community’s culture and heritage.

• A self-construction process and local supplier participation.

• Community-member training in building, to support the local economy.

• A variety of housing types: townhouse, duplex, and single- family.

HEALTH FOCUS

• Non-toxic building materials, including mould-resistant drywall and other new products.

• Low-emission paints and formaldehyde-free insulation.

• Engineered hardwood floors, polished concrete, and tile floors to reduce off-gassing.

• Cabinets and shelves of materials that do not emit formaldehyde or other harmful vapours.

• Lead-free faucets.

• High-efficiency fans, to prevent moisture build-up and mould growth.

• Rainscreen technology, to handle moisture and prevent mould growth.

• Natural day lighting.

• Sun, wind, and earth energy systems.

ENERGY EFFICIENCY

• Homes oriented to the south, to take advantage of the sun’s heat.

• Solar energy to preheat water.

• Metal roofs to provide solar heat.

• Solariums, to retain heat and permit year-round gardening.

• Earth tubes, to preheat or cool incoming outside air.

• Constant recycling of heat throughout the house.

• Radiant floor heating systems, to eliminate the need for a furnace.

• Wind generators, to supply supplemental power.

• A well-insulated building envelope.

• Energy-efficient appliances, lighting fixtures, windows, and doors.

COST EFFICIENCY

• Higher-density buildings, to reduce overall building, land, and infrastructure costs.

• FlexHousing™ design, to reduce future renovation costs.

• Low maintenance, due to durable materials and finishes, plus ability of community to do most repairs.

• Lower heating and electricity costs due to energy efficiency and solar orientation.

• Easily duplicated, modular design elements.

RESOURCE EFFICIENCY

• Durable building materials, including metal roofing, full dimension rough-cut cedar siding, logs, concrete and wood flooring, wood countertops.

• Multi-functional elements: Concrete-finished floor stores heat and is part of the structure. A metal roof provides long-lasting protection and solar heat.

Solariums used for growing plants and heating homes.

Earth tubes pre- condition air for heating and cooling.

• Water-efficient plumbing fixtures such as low-flow toilets.

• Modular construction to reduce construction waste.

• Recycled building materials such as plastic lumber for sill plates and strapping; refinished power and telephone poles for interiors, carports, and carvings;

recycled steel in metal roofs; high recycled-content batt insulation.

• Indigenous building materials such as gravel, wood, logs, and river rock.

• Use of local suppliers to support the local economy.·

• Drought-tolerant plantings, requiring less irrigation.

• Increased housing density and a variety of housing types to maximize land use.

• Easily convertible, to provide more housing units without using more land.

The Seabird Island First Nation Sustainable Community Demonstration Project was showcased through several tours and workshops at the CMHC-sponsored Aboriginal Housing Symposium at Harrison Hot Springs. In addition, a 30-minute video, entitled ‘In a Sacred Way We Build,’ is available for general broadcast on Canadian television and for use as a First Nations community resource. For more information related to this article or the Seabird Island project, please contact:

Rob Sieniuc MAIBC, MEDes(Arch) Broadway Architects: Sieniuc + de Ridder Vancouver, BC

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.